Overcoming Challenges in Sorting Services for Product Quality Improvement

cbsc-global.my.id - Overcoming Challenges in Sorting Services for Product Quality Improvement

In the competitive landscape of electronics and automotive production sectors, the demand for high-quality products is very important. Companies are increasingly relying on third-party quality inspection, verification, rework, assembly, logistics management, and supply chain manufacturing to ensure their products meet stringent standards. One of the critical stages in this process is sorting services, which can significantly impact the overall quality of the final product. This article delves into the challenges faced in sorting services and the strategies employed to overcome them, ensuring that pre-shipment inspections are not just a formality but a guarantee of excellence.

The Importance of Sorting Services

Sorting services are essential in identifying and segregating defective components or products before they reach the consumer. This process not only helps in maintaining quality but also reduces the cost associated with returns and repairs. However, sorting is not without its challenges. The primary issues include the handling of high-volume orders, maintaining accuracy in detection, and the need for rapid turnaround times.

Challenges and Solutions

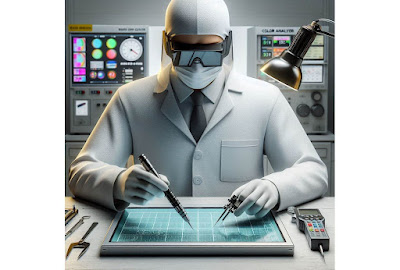

One of the main challenges in sorting services is the integration of advanced technology with human expertise. Automated sorting systems have revolutionized the industry, but they require skilled personnel for operation and maintenance. To address this, companies invest in continuous training and development programs for their employees, ensuring that they are adept at using the latest technologies.

Another challenge is the variability of defects. In the electronics and automotive sectors, the range of potential issues is vast, from minor cosmetic blemishes to critical functional failures. To manage this, sorting services employ a combination of visual inspections, functional testing, and automated checks. This multi-faceted approach ensures a comprehensive assessment of each product.

Logistics also pose a significant challenge, especially when dealing with global supply chains. Timely coordination between sorting facilities and manufacturing plants is crucial to prevent bottlenecks. Implementing robust logistics management systems and predictive analytics can help streamline the process, ensuring that sorted products are delivered on schedule.

The Role of Third-Party Quality Inspection

Third-party quality inspection services play a vital role in the sorting process. They provide an unbiased assessment of products, which is crucial for maintaining trust with customers. These inspections are often rigorous and cover a wide range of criteria, from material quality to functional performance. By leveraging third-party services, companies can assure their customers that their products have undergone stringent evaluations.

Conclusion

As the electronics and automotive production sectors continue to evolve, the role of sorting services in maintaining product quality becomes increasingly significant. By overcoming the challenges associated with third-party quality inspection, verification, rework, assembly, logistics management, and supply chain manufacturing, companies can ensure that their products stand out in the market. With meticulous pre-shipment inspections, businesses can confidently deliver products that meet and exceed customer expectations, solidifying their reputation for quality and reliability.

No comments:

Post a Comment